BUILDING SYSTEM IN WOOD

Why choose Platform-Frame System

The Platform-Frame system is ideal for building houses and other prefabricated multi-storey wooden buildings. With this system it is possible to realize individual and condominium residential buildings up to four floors.

For this reason it is particularly suitable for wood realizations for Social Housing: Facilities for emergency housing and shared public spaces.

The system provides excellent insulation and earthquake capacity: boasting the highest coefficient of structure between the construction types of wood. It also represents an economic methodology, easy to assemble.

What is Platform-Frame System

In building system Platform-Frame every floor of the building serves as a platform for the upper floors. The system, born in Northern Europe, is widespread in North America.

Each wall or ceiling is formed from laminated wood vertical posts or KVH placed at intervals. It is positioned on the outer sides of the structural covering panel in pine plywood or OSB that completely covers the frame, through the use of improved adherence nails and metal angular.

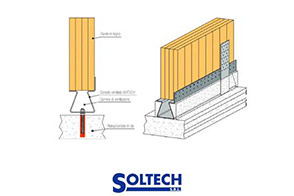

The Platform-Frame system is generally based on reinforced concrete stalls. The connection between the wooden structure and foundations is ensured by means of suitable threaded rods in steel or expansion plugs.

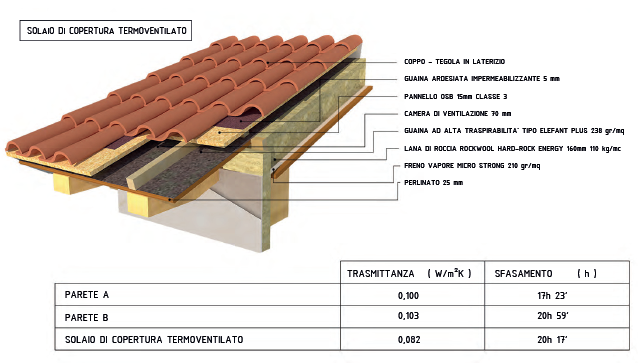

Stratigraphy:

- Laminated spruce beams Gl 24h quality certified according to EN 14080 views

- Perlinato solid spruce quality AB sp. 32 mm melamine view with impregnating biocide sample.

- Steam brake Riwega Micro strong 210 gr / sqm with Siga adhesive bands

- Rockwool Hardrock Energy Rockwool 110 Kg / Mc sp 200mm;

- highly breathable sheath Elefant plus 238 gr / m²;

- ventilation chamber made from moral pine timber autoclave 40x70mm

- OSB 15 mm Classe 3;

- Slated sheath 4.5 kg m -15 ° laid hot and guaranteed;

- network parainsetti

- Portuguese tile laid standard red with polyurethane foam;

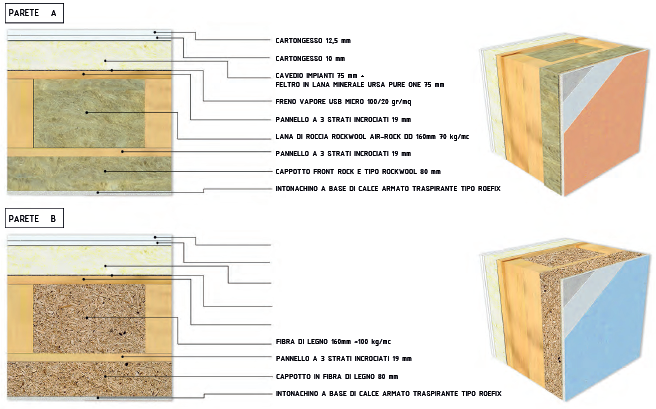

Stratigraphy:

- Breathable plaster reinforced Roefix certified and guaranteed (color pigment Roofix clear folder 1st tone);

- Frontrock Rokwool coat Panel E max 80 mm thick;

- Support panel three-layer cross fir for structural use sp.19 mm;

- Spruce beams KVH 60×160 mm C 24 certified according to EN 14080

- Rockwool panel Airrock DD sp 240mm density 70 Kg / m3 interposed between the uprights;

- Support panel three-layer cross fir for structural use sp.19 mm;

- Steam brake Riwega Micro strong 210 gr / sqm with Siga adhesive bands taped seams to prevent air leakage; (including air-stop accessories)

- Riser for thickness 50 mm implants made of profiles 50×60 mm solid spruce;

- Atrium filled with water-repellent felt Mineral wool URSA Pure One 50 mm;

- Plasterboard mm. 12.5 plastered ready for painting;

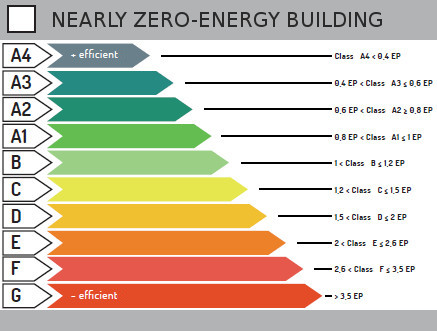

NEW ENERGY EFFICIENCY CLASSES ACCORDING TO DM 26 JUNE 2015 (CLASSI A1, A2, A3, A4)

The energy efficiency class of a building is determined on the basis of the global non-renewable energy index of the building EPgl, nren, through a comparison between a scale of pre-fixed classes each of which represents a well-defined interval of energetic performance.

The energy efficiency class is indicated by a letter where g represents the class with the highest performance index (the highest

energy consumption) whereas A represents the class with the best performance index (the lowest energy consumption).

A number, next to the letter A, identifies the levels of energy performance in growing order starting from number 1 (representing the lowest energy performance level of class A).

Picture – New scale of classification of buildings energy performance on the basis of global non-renewable energy performance index EP.

Choosing houses in A ENERGY CLASS:

- means ECONOMY FOR FAMILIES, who can save up to 70% on total energy costs.

- means CONSERVATION OF THE VALUE OF BUILDING OVER TIME if compared to houses built with previous technologies which will be less and less requested.

- means RESPECT FOR THE ENVIRONMENT WE LIVE IN because there will be less harmful emissions and less waste.

Others Partners

Rotho Blaas offers wood professionals a wide range of latest products and easy to use: fastening systems such as structural bolts and external, retractable junctions, angular and shoes, anchors and all necessary hardware to the carpenter; systems for waterproofing and airtight seal casing, including the specific accessories for the sealing and the ventilation; solutions for noise reduction, for reduction of noises in the housing and a greater comfort.

Rotho Blaas offers wood professionals a wide range of latest products and easy to use: fastening systems such as structural bolts and external, retractable junctions, angular and shoes, anchors and all necessary hardware to the carpenter; systems for waterproofing and airtight seal casing, including the specific accessories for the sealing and the ventilation; solutions for noise reduction, for reduction of noises in the housing and a greater comfort.

The Technical Directive laying A + describes the main guidelines for correct use of the proposal of the Systems Technology A +. With the Technical Directive A + ensures a high degree of thermal insulation of the external surfaces, the absence of thermal bridges, air-tightness. With the laying Directive A + ensures an accurate realization.

The Technical Directive laying A + describes the main guidelines for correct use of the proposal of the Systems Technology A +. With the Technical Directive A + ensures a high degree of thermal insulation of the external surfaces, the absence of thermal bridges, air-tightness. With the laying Directive A + ensures an accurate realization.

Contacts

Wooden Buildings s.r.l.

Via della Stazione 67

60022 Castelfidardo An

T 071 291 63 13

F 071 214 68 90

info@woodenbuildings.it